Welcome to Nirmal Group since 1973

Welcome to Nirmal Group since 1973

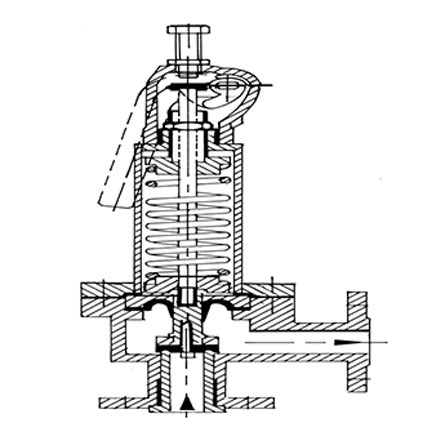

Nirmal conventional spring loaded safety relief valves are manufactured as quality product and performance conforming to ASME/API. These valves are designed to release excess pressure in the vessel/line when pressure in the vessel/line exceeds the set value (adjustable by set screw) the valve opens, releasing the excess pressure and reclose after normal conditions have been restored.

These are suitable for most of the fluids and find applications in Chemical, Process Industries, Fertilizers and Petrochemical plants, Refineries, Pharmaceutical and Food processing plants, Thermal and Nuclear Power plants etc.

Proportionate Type : In proportionate type opening of the relief valve is in direct proportion to the rise in pressure above the set point. The reset of the valve is very near to set point and hence there is very less loss of fluid because pressure is always maintained at ‘Set point’.

Popping Type : When line pressure rises beyond set point valve pops open and heavy discharge of gas takes place, resulting in bringing

down the pressure in the line below the set value.

The operation of a conventional spring loaded pressure relief valve is based on a force balance.

The spring load is preset to equal the force exerted on the closed disc by the inlet fluid when the system pressure is at the set pressure of the valve. When the inlet pressure is below the set pressure, the disc remains seated on the nozzle in the closed position. When the inlet pressure exceeds set pressure, the pressure force on the disc overcomes the spring force and the valve opens. When the inlet pressure is reduced to level below the set pressure the valve recloses.

Design : Universal design, same trim suitable for gas and liquid service.

Set pressure : As low as 0.25 bar to as high as 200 bar.

Sizes : Inlet sizes range from 1/2” to 3”.

Tamper Resistant : An adjusting screw lock nut and protective cap is standard to discourage tampering with pressure setting.

Variety of Materials : Valve body, trim and ‘O’ ring are available in various material combinations for process fluid compatibility.